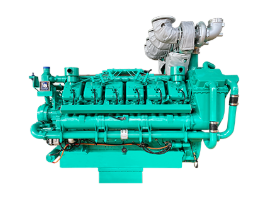

Diesel Engine

Generator Set

In modern industry, the stable operation of generator sets is crucial, and real-time assessment of their health status through monitoring technology can effectively prevent failures and reduce maintenance costs. The following will provide a detailed introduction to the relevant content.

Monitoring technology type

Vibration monitoring technology: using vibration sensors to collect vibration signals during the operation of the generator set. During normal operation, the vibration amplitude and frequency of each component of the generator set are within a certain range. If abnormalities occur, such as bearing wear or rotor imbalance, the amplitude of the vibration signal will increase and the frequency will also change. By analyzing these signals, it is possible to determine whether there are any hidden faults in the equipment.

Temperature monitoring technology: using temperature sensors to monitor the temperature of key parts of the generator set, such as the engine cylinder block, windings, bearings, etc. Excessive temperature is often a precursor to equipment failure, for example, high winding temperature may indicate insulation damage and cause short circuit faults. By setting a reasonable temperature threshold, timely alarms can be triggered when the temperature exceeds the range, so that measures can be taken.

Oil analysis technology: Regularly collect engine lubricating oil samples, analyze the content of wear particles, pollutants, and changes in physical and chemical properties. The size and quantity of wear particles can reflect the degree of wear of internal components of the engine. If the pollutant content exceeds the standard, it indicates that the lubricating oil is contaminated and affects the lubrication effect. Potential mechanical failures can be detected in advance through oil analysis.

Key monitoring parameters

Speed: The speed of the generator set directly affects the output frequency and power stability. During normal operation, the speed should be maintained near the rated value. Excessive speed fluctuations may be caused by faults in the speed control system or sudden load changes, which can affect the quality of power output and even lead to equipment damage.

Voltage and current: Monitor the amplitude, phase, and harmonic content of the output voltage and current. Unstable voltage or abnormal current may indicate problems with the electrical system, such as short circuits, grounding faults, etc. Excessive harmonic content will increase equipment losses and affect equipment lifespan.

Pressure: including engine oil pressure, fuel pressure, and intake pressure. Insufficient oil pressure can lead to poor lubrication and accelerate component wear; Abnormal fuel pressure affects combustion efficiency and reduces engine power; Abnormal intake pressure can affect the inflation efficiency of the engine, thereby affecting its performance.

By comprehensively utilizing various monitoring technologies, real-time monitoring and analysis of these key monitoring parameters can be carried out, which can timely and accurately evaluate the health status of the generator set, provide strong basis for equipment maintenance and management, and ensure its safe, stable, and efficient operation.